1. Technical Data Sheet:

|

Model |

BG-215 |

BG-216 |

BG-218 |

BG-2113 |

|

Imported materials and dimensions (mm) |

160*400 |

230*500 |

300*680 |

450*700 |

|

Flying the number of |

2 |

2 |

2 |

2 |

|

Knife roll speed |

592 |

590 |

650 |

500 |

|

Maximum diameter of the processing of raw materials(mm) |

160 |

230 |

300 |

450 |

|

Chip size (mm) |

30 |

30 |

30 |

38 |

|

Production capacity(tons/h) |

8-10 |

15-20 |

30-35 |

45-50 |

|

Power of main motor(kw) |

45 |

55 |

110 |

200-250 |

|

Feed roller motor power (kw) |

2.2-3 |

3-4 |

4-5 |

7.5*2 |

|

Pump motor power(kw) |

1.5*1 |

1.5*1 |

1.5*1 |

3*1 |

|

Weight(kg) |

2990 |

4070 |

7000 |

11840 |

|

Overall dimensions(mm) |

1470*1550*970 |

1800*1900*1210 |

2200*2150*1500 |

3670*2517*2050 |

|

Electrical power transmission machine(kw) |

3 |

3 |

3 |

3 |

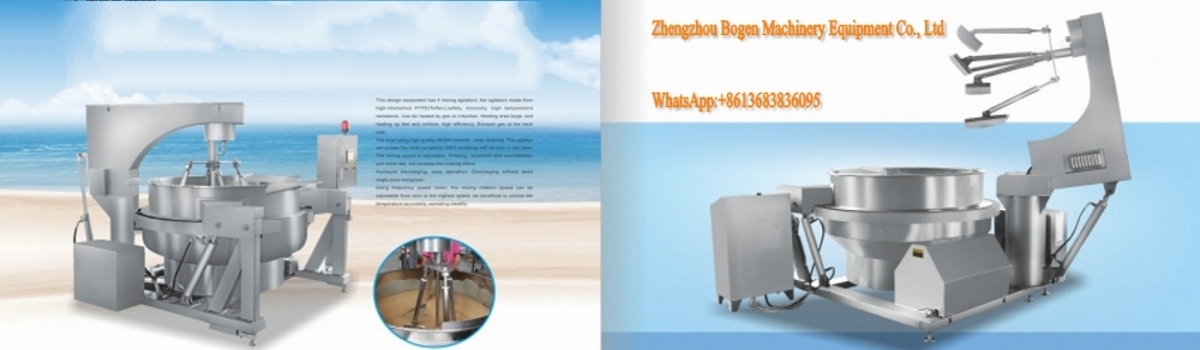

2. Introduction:

(l). It is the special equipment of producing chips.

(2). It is widely applied in particleboard factory, and the high density fiberboard, stubble, biomass power plant, wood factory industries before production units.

(3). This machine is designed for cutting machine, grinder machine designed with high precision, simple operation, easy to use, can grind various types of cutting machine, screw machine.

3. Features:

(1). Hydraulic system: From the pump to oil cylinders, the cover can be opened, it is easy to change the blade. It can

raise the upper feed roller in maintenance, it is easy to adjust the space between fly cutter and knife.

(2). Two or three knives are installed on knife roller with specialized in manufacturing, the fly cutter is fixed on the knife roller through the bolt. According to the different thickness of raw materials by cutting, feed roller assembly by hydraulic system can fluctuate within a certain scope. Cutting down the qualified materials through the screen mesh from bottom of large discharge will cutting again in the inner of this machine.